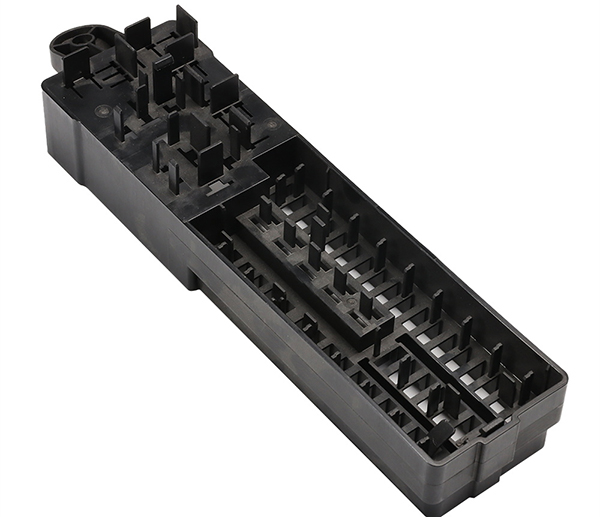

The grille is also an important part of the front styling. Together with the front bumper and headlights, it forms the entire front of the car. For aesthetic reasons, the grille is generally chrome-plated.

- Principles of grille material selection

As the air intake grille is close to the engine compartment, it is often subject to high temperature baking and is generally an electroplated part with the following material requirements:

Good plating properties, conducive to plating;

good weather resistance, to prevent deformation, ageing etc. under high temperature exposure

good stability, which cannot be deformed during long-term work;

good flowability to meet the requirements of the injection moulding process

Good processing properties to facilitate injection mould design.

- Performance of commonly used grille materials

The common materials used for air intake grilles are ABS or PC/ABS alloy, both of which have good plating properties.

ABS resin is a light yellow more or bead-like opaque resin with low water absorption, high impact resistance, rigidity, oil resistance, cold resistance, chemical resistance, it is easy to plating, easy to form and low price.

PC/ABS alloys are thermoplastics made from an alloy of polycarbonate (Polycarbonate-PC) and polyacrylonitrile (ABS), with ABS grafting, maleic anhydride, acrylic acid, amine and other compatibilisers generally added during processing to increase compatibility. The PC/ABS alloy consists of a PC phase, a SAN phase and a grafted PB rubber phase with a complex microstructure. It is a very cost effective plastic material with good performance of both.

Translated with www.DeepL.com/Translator (free version)