Stay Good, Strive to be Better

Welcome to GBM Mold!

Since set-up in 2012, GBM hold a strategic mission – to build qualified molds in a fast turnaround delivery,with high cost performance ratio. This mission lives on today and sets us apart from other shops.

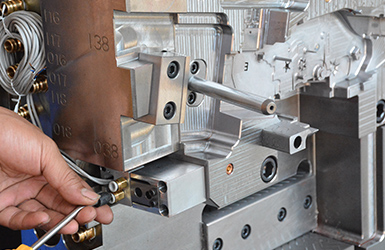

GBM is a middle-sized manufacturer for precision plastic tooling, injection moulding, stack molding, single-shot and multi-component injection molding (2-K and 3-K, 2K with metal inserts ), rotary 2-shot molding and vertical insert molding ( metal-to-plastic molding).

Our customers come from various fields, such as automotive, electric, medical,consumer, industrial and many others. We have an European after-service center in Netherland to support our European customers.

GBM-MOULD

Our Team

Joyce Wang

Marketing Director

18 years in the mold industry, smooth communication with domestic and foreign customers, seamless connection

Andy Gao

General Manager

He is an injection mold engineer with 20 years of experience in the industry and has been hired by US customers as their full-time mold injection consultant for over 10 years.

Thomas Peng

Engineering Manager

Mold Specialized in the field of manufacturing, 20 years of deep plowing, focus on the industry.

What Our Customers say?

–Tier 1 Supplier, USA.

You can never go wrong from purchasing mold from GBM. Top level quality and service!

— Plastic Injection Manufacturer, UK.

I think GBM is good for “difficult” and “high value” projects! We would happily act as a reference for GBM if anyone asked you for UK company to confirm your quality / abilities.

Suppassessment

We have evaluated your performance in year 2018, the points for the overall evaluation (max100) are calculated by the sum of the detailed evaluation results.

Following the detailed evaluation result:

Quality 95 Points

Service 100 Points

Time 93 Points

Average 96 Points

Due to your performance we classified you as:

A-Supplier一Points 291B-Supplier-Points 75<X<90C-Supplier- Points < 75

As you can see, you are evaluated as an A-Supplier in our company.

Facts and Figures

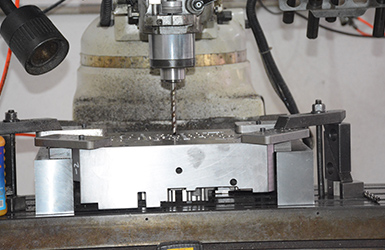

Tool making: 7 designers and CNC programmers, 6 mold fitting operators, 2-shift CNC milling and EMD. 100% inspection for electrodes and main mould components.

Mold shop 1800 ㎡

Total Employees 47

Capacity 250 molds a year

Turnover in 2017 4 Million USD

Max. mold weight 7.5 Ton mold

T1 on time rate in 2017 96%

Average time from T1 to shipping approval 1 to 4 weeks

Fast project lead time eg: Stack mold-9 weeks from design to mold shipping

GBM–15 years of technical precipitation

Plant equipment