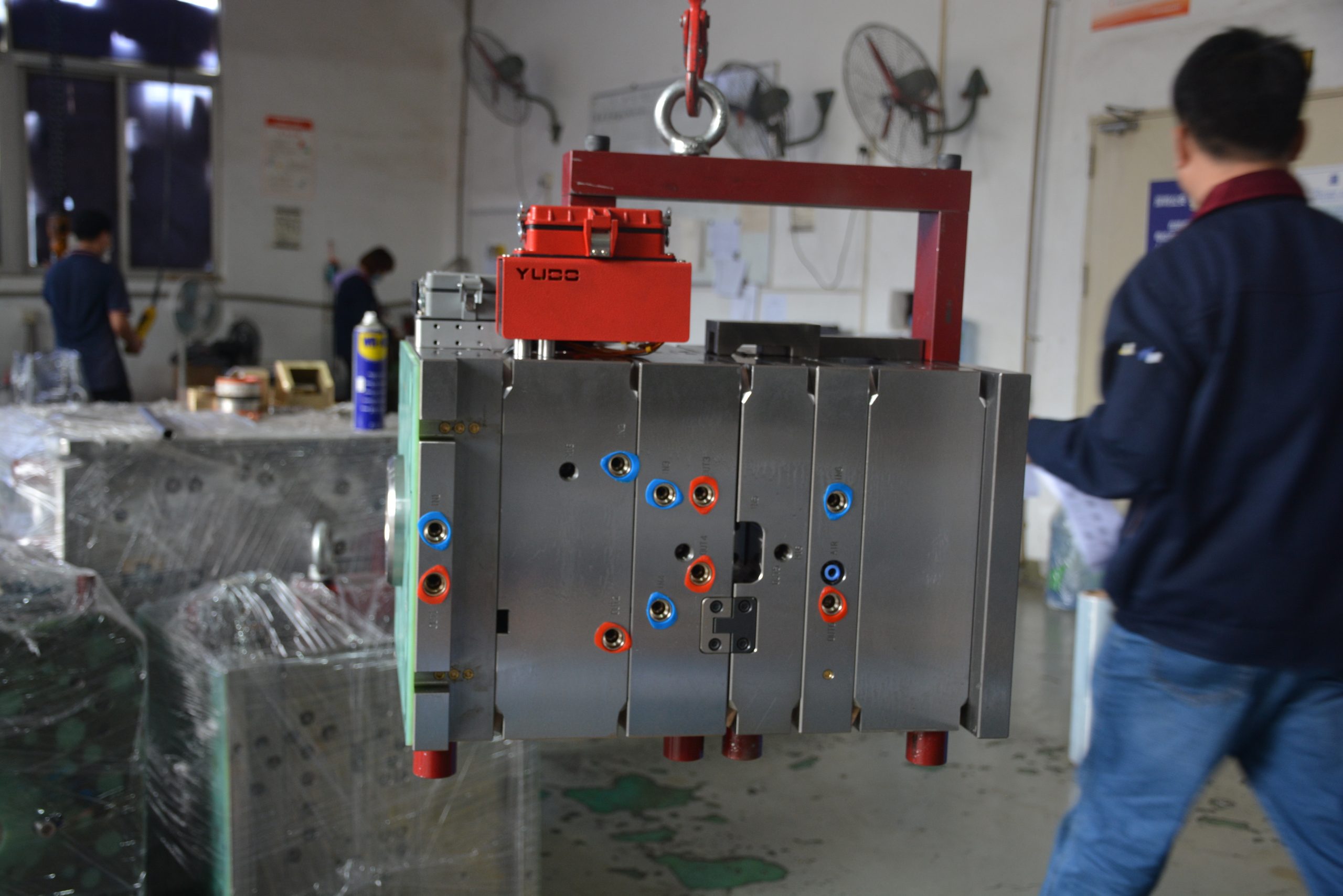

Analysis, design and manufacturing of moulds are made in house. We have 7 tooling engineers, including mold designers and CNC programmers. For mould making we conduct 2-shift operation of EDM and CNC milling.

Our tooling processes include: Drilling and tapping, CNC milling, steel hardenning, grinding, EDM (Electric Discharge Machining), wire-cutting, SPI standard polish, texture, laser engraving, mould fitting and assembly, injection.

Details determine the quality

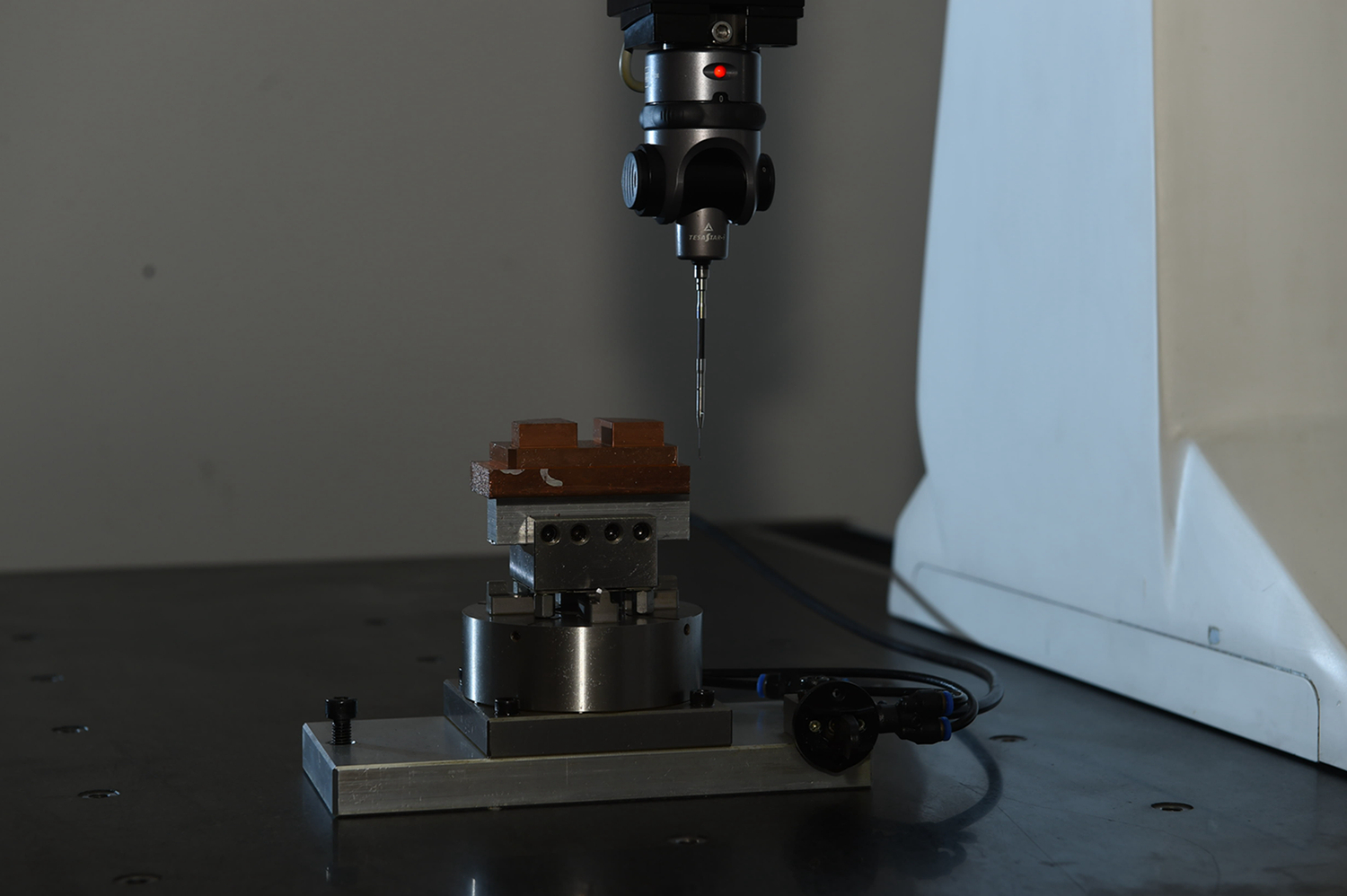

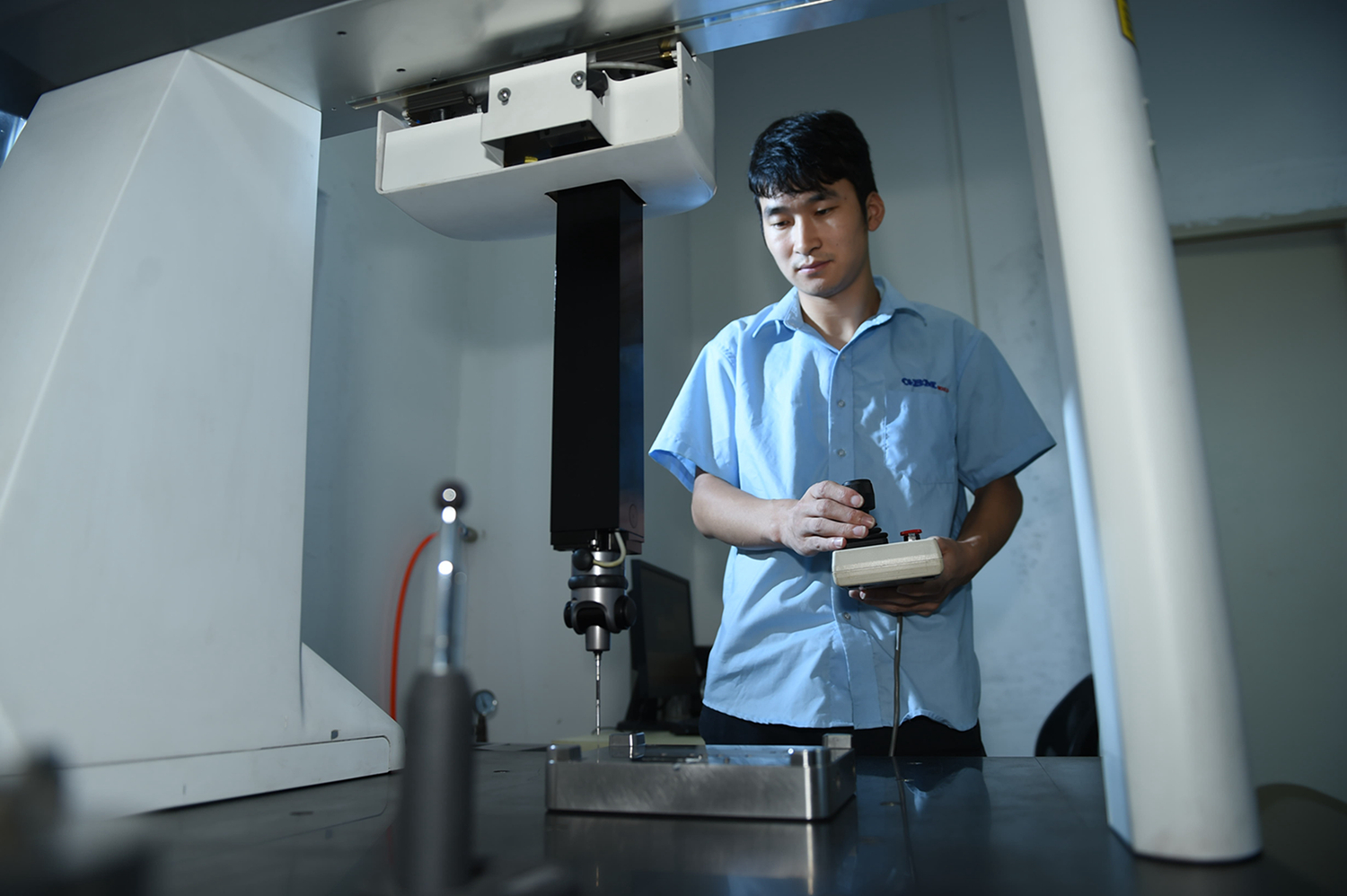

Quality is the lifeblood of GBM, and reputation is our future. So we will carry out strict quality control on the whole project

Incoming Material Inspection

Copper Public Inspection

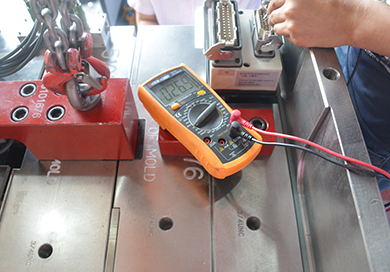

Steel hardness test

Process testing

Three-dimensional testing

Final quality control

More than a mold, it is the whole life cycle of guarding

- Provide full life-cycle service support from mold design to continuous mass production of products

- Provide unconditional technical support for any problems with the mold during mass production

- Continuous after-sales follow-up service, proactive provision of mass production processing technical consulting services

Molds are custom developed and you may encounter some challenges. GBM is with you.

GBM has been cooperating with European and American customers for more than ten years, familiar with international mold standards, understanding customer needs, and has a deep understanding of two-color molds, vertical metal insert molds, precision connector injection molds, etc.