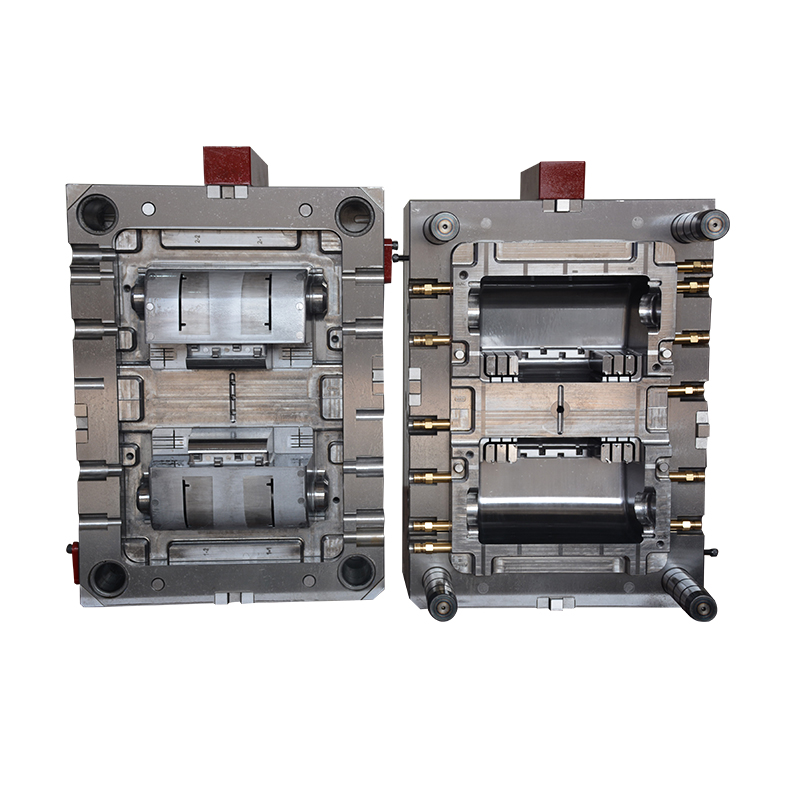

Plastic Mold Advantages:

HIGH ACCURACY: Plastic mold making can achieve high precision molding and is suitable for manufacturing products that require precise size and shape.

Production efficiency: once the plastic mold manufacturing is completed, the production speed is relatively fast, can mass produce the same product, reduce production costs.

Material diversity: plastic mold can be adapted to a variety of plastic materials, to meet the material requirements of different products.

Complex structure: plastic mold can make complex structure and shape, traditional processing methods are difficult to reach.

Saving raw materials: Plastic mold manufacturing process is relatively less waste, which contributes to the saving of raw materials.

Plastic mold disadvantages:

High manufacturing cost: manufacturing plastic mold requires professional design and manufacturing, the initial investment is larger, less economical for small batch production.

Longer cycle: plastic mold manufacturing cycle is longer, may affect the product time to market.

Maintenance difficulties: plastic molds may be worn or damaged in the production process, requiring regular maintenance and repair.

Advantages of traditional processing methods:

Wide range of applications: Traditional machining methods can be applied to a wide range of materials, not just plastics.

Low initial investment: Traditional machining methods usually do not require large-scale mold manufacturing and are suitable for small batch production.

Flexibility: Manual adjustments and modifications can be made during the process, making it highly adaptable.

Disadvantages of conventional machining:

Relatively low precision: traditional processing may not be able to achieve the high precision requirements of plastic molds.

Lower production efficiency: For mass production, traditional processing methods may be more time-consuming and labor-intensive than plastic molds.

Restrictions on complex structures: traditional processing methods are difficult to create complex product structures and shapes.

In summary, the choice of plastic mold or traditional processing depends on the requirements of the product and the scale of production. If you need high-precision, complex structure of the product, and the production scale is large, plastic mold may be more appropriate. For small batch production or low precision requirements, traditional processing methods may be more advantageous.