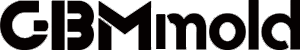

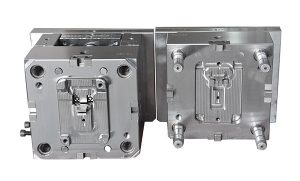

There are many factors that affect the life of the plastic shell mold, this article is mainly about the plastic shell mold line position action. 1, plastic shell mold slider action should be smooth, not stagnant. Need to ensure that the parts are not deformed, can not appear dead action, uneven, loose and other phenomena;.

2, the big slider guide sliding surface to open oil groove.

3, the big slider must have cooling waterway.

4、Slider and slide part of the HVE6 combination structure, not loose;

5, when the sliding stroke is too long, must be in the mold base to increase the guide, in general the guide length to reach the width of about 1.5 times suitable, the core extraction guide in the slider and the guide rail with the place, to guide the guide rail in the guide section of the slider 2/3 tube placed in the guide rail;

6, oblique guide hole and oblique guide with must leave a gap greater than 0.2mm, prohibit the same specification with;

7, the angle of the oblique guide is less than the slope of the line position wedge surface of 2 degrees, large slider wedge block, must be extended into the lower mold 15-20 mm, and the oblique surface of the 10-degree interlocking counter-pressure.

8, round face slider combination of cavities, longitudinal and round face slider angle, oblique guide column angle of each 2 degrees, prohibit the same size slider, slider z final position above the mold, must use the catapult to push or pull, the form can not use the wave beads, so as not to slider in the plastic shell mold mold mold hit the round face slider and oblique guide column.

9, in addition, all rows of rubbing surface must be installed wear plate, rubbing surface length greater than 30mm, width greater than 50mm. detail and rows of pressure plate need to be quenched and hardened 52HRC or more, the larger part of the plastic shell mold according to the requirements of nitriding or hardening before molding.